Modern construction demands solutions that combine performance with practicality. Our innovative ceramic bead-based coatings offer an advanced protective system that goes beyond conventional paints and finishes. By incorporating millions of microscopic hollow ceramic spheres into a patented matrix, we’ve created a coating system that delivers exceptional results across multiple performance categories.

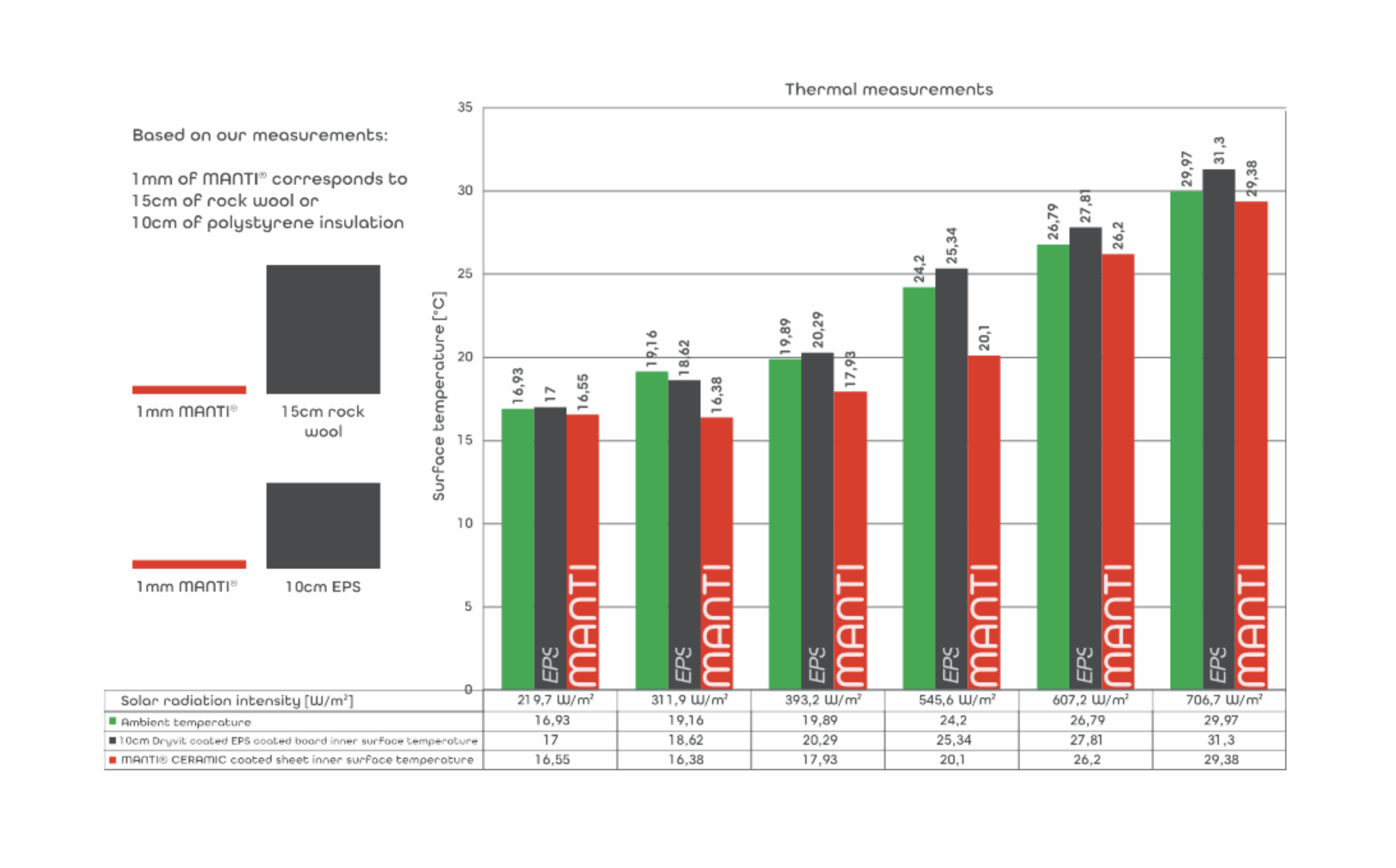

The ceramic bead matrix enhances thermal resistance, providing superior insulation compared to traditional coatings—keeping interiors cooler in summer and warmer in winter.

Applies like standard paint but delivers multi-functional performance, reducing the need for additional insulation layers or complex construction modifications.

Combines protection and insulation in one system, cutting material, labor, and long-term maintenance costs—a smarter investment for modern buildings.

Ceramic microspheres dominate insulation by simultaneously attacking all heat transfer modes (conduction/convection/radiation) at multiple length scales. Their tunable nanostructure and compatibility make them the material of choice for extreme environments, from spacecraft to skyscrapers.

Achieves up to 40% higher R-value than conventional coatings, ensuring superior insulation and indoor comfort all year round.

Reduces surface temperatures by 15–35°C, minimizing heat absorption during hot summer days and extending surface lifespan.

Cuts cooling energy costs by 10–15% for commercial buildings by reducing the demand on HVAC systems.

Engineered to last over 25 years with proper maintenance, delivering reliable long-term protection in the harshest conditions.

Proven to withstand over 5,000 hours in salt spray tests, making it ideal for coastal or industrial environments.

Remains intact through 1,000+ freeze-thaw cycles without cracking or peeling, ensuring reliable performance across extreme climates.

Cures to the touch in just 8–24 hours, depending on environmental conditions—ideal for tight project timelines.

Applies easily in temperatures from 5°C to 40°C, allowing flexibility in both cold and hot weather conditions.

Delivers 30–40% more surface coverage than conventional thick-coat systems, reducing material use and application time.

Reduces overall maintenance expenses by 40–60% compared to traditional systems—less upkeep, more savings.

Delivers long-lasting performance with 12–15 years between recoating, cutting downtime and costs.

Enhances thermal performance without structural reinforcement, making it ideal for retrofits and lightweight applications.

Reduces surface condensation by 60-70% compared to non-breathable coatings

Maintains stable humidity levels between 45-55% RH on treated surfaces

Dew Point Optimization: Keeps substrate temperatures above condensation threshold in most climates

MANTI coating system is specially engineered to provide optimal humidity permeability while maintaining superior protection. Unlike conventional coatings that trap moisture or break down under damp conditions, our technology creates a “breathable” barrier that actively manages humidity transfer—critical for long-term building health and occupant comfort.

pH-balanced formulation (8.5-9.2) creates inhospitable environment for microbial growth

0% organic content in ceramic beads eliminates food source for fungi

The unique ceramic bead technology creates microscopic air pockets that act as both insulation and stress-relief zones, allowing the coating to expand and contract with building movement while maintaining continuous protection. Unlike rigid insulation boards or fragile finishes, our solution provides seamless, monolithic protection that adapts to your building’s needs.

Would you like us to provide specific performance data for your climate zone or building type? Our technical team can prepare customized projections for your project’s expected energy savings and durability performance.